Welcome To Pawan Castings

A Leading Manufacturer Of Steel Products In NorthEast India

As one of the prominent steel manufacturers in Assam, Pawan Castings offers a range of TMX Bars, Angle Patti, MS Coil, MS Square Bar, MS Angle and MS Round using advanced and modern steelmaking and rolling technology ensuring safest constructions.

Our Partners

OUR PRODUCTS

Meghalaya's First TMX Bars Manufacturer With German 'THERMEX' Technology

TMX Bars

Builds infrastructure that needs a high level of capacity to handle high pressure and increased load bearing capacity.

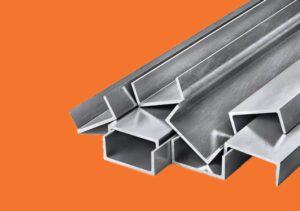

MS Flate

Supreme quality with precise measurements, durability, high tensile strength, and resistance to corrosion.

MS Square Bar

With its good quality, pliability, and stiffness, it may be welded, drilled, and cut to suit your requirements.

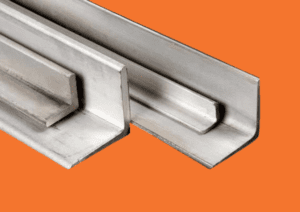

MS Angle

The most frequently used MS steel angles are the ones forming a 90-degree angle with two sides of equal length and width.

MS Round

It is a highly machinable metal that can be formed into intricate shapes without adding proportional stress.

MS Coil

It has superior quality with a premium finish in the range of grades, thicknesses, lengths, weights and durability.

MS Z Angle

These angles deliver flawless performance as they are fabricated in compliance with the latest standards.

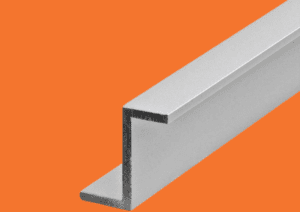

MS Chanel

MS Channel essentially carries horizontal gravitational forces and is used for bus body, EOT cranes and many more engineering industry needs.

WHY CHOOSE PAWAN CASTINGS ?

BIS

ACCREDITED

Quality in accordance with the Bureau of Indian Standards that you can test at our Rods 'n' Bars locations.

EXCELLENT

FLEXIBILITY

The Pawan Castings rebars are developed using a cutting-edge Tempcore Quenching technique, which provides them good bendability and workability.

SUPERIOR SEISMIC

RESISTANCE

The most modern steel which is resistant and provides protection to any natural disasters or any hazards like earthquakes.

REGULATION OF CHEMICAL COMPOSITION

Hot rolled from a premium billet that is 100% captive and has a regulated chemical composition with low levels of phosphorus, sulphur, and carbon.

AFTER - SALES

ASSISTANCE

With our extensive distribution network we are constantly available for you and ensure your full satisfaction.

PROTECTED, INVULNERABLE & GUARDED

North East's Safest and Guarded Steels

Get Free Quote

Fill the form below to get started your project

THE STORY

ABOUT US

PAWAN CASTINGS PVT LTD., is a Meghalaya based ISO 9001 : 2015 accredited and Bureau of Indian Standard registered TMT bar manufacturing company. The company was incorporated in the year 2001 and for the last 21 years we have been manufaturing TMT bars at our facility located at Harlibagan, Byrnihat, underRi-bhoi district in Meghalaya. The annual production capacity of our plant is about 54,000 M.T. of finished steel.

Need High-Function Bar

Wire Rod Products?

We can offer abundant steel types and sizes to meet diversified and sophisticated needs in each field.

WHAT WE DO

Our Wide Range of Products.

MS Coil, MS Flate

Hot-rolled steel is produced by a rolling method at temperatures.

MS Square Bar

Hot-rolled steel is produced by a rolling method at temperatures.

MS Angle, MS Z Angle

Hot-rolled steel is produced by a rolling method at temperatures.

MS Round, MS Chanel

Hot-rolled steel is produced by a rolling method at temperatures.

The Process

Quenching

Hot-rolled steel bars from the mill undergo quick cooling with a water spray which results in the creation of a hard outer martensitic rim. The core of the bar remains hot and austenitic. These two layers of the TMT bar offer it both strength and ductility.

Self-Tempering

The steel bars are then allowed to “self-temper”. In this step, the core of the bar, which could not get cooled in quenching, is allowed to transfer its heat to the outer martensitic layer, thereby “tempering” it and enhancing its strength.

Atmospheric Cooling

Finally, the steel bars laid on a cooling bed and allowed to rest at normal temperature. This allows the transformation of the soft, inner austenitic core into a ferrite-pearlite structure. Thus, the final product has a hard order layer which is tough and a ductile core.

Commited to High Quality

Service

Pawan Castings is dedicated to providing quality TMX Bars and steel products

that offer dependability and strength to get the desired outcome and value to our customers.

FOUNDER & DIRECTOR

LATE MADAN LAL MITTAL

(1945-2021)

Late Madan Lal Mittal, a ‘Karma-Yogi’ by nature and hard work has been the Founder and guiding force behind Mittal Group of Industries. He started from trading and setup the industrial group comprising of Steel, Cement, AAC Blocks and other ventures of repute. He has been one of the leading entrepreneurs of North East. His creation superior quality “Mittal Gold TMT” is one of leading and sought after brand in entire North Eastern Region.

THEY SAY

Testimonials

WHAT’S NEW

Our Features

Pawan Castings: A Leading Manufacturer Of Steel Products In North-East India

PAWAN CASTINGS PVT LTD. is a Meghalaya-based ISO 9001: 2015 licensed and Bureau of Indian Standard registered TMT bar manufacturing company. The company was incorporated in the year 2001 and for the last 21 years, we have been manufacturing TMT bars at our facility located at Harlibagan, Byrnihat, the underRi-bhai district in Meghalaya. The yearly production capacity of our plant is about 54,000 M.T. of finished steel.

Pawan Castings manufacturers are located in Guwahati (Assam), Mizoram (Aizawl), Tripura (Agartala), Dibrugarh, Nagaland (Dimapur), Manipur (Imphal), Arunachal Pradesh (Itanagar), Nagaland (Kohima), Silchar, and Meghalaya (Shillong).

SIGN UP OUR

Newsletter

Get the latest news and special offers

COMPANY

PRODUCTS

USEFUL LINKS

ADDRESS

Corporate Address

Ground Floor, Shanti Sadan, Narayan nagar, Kumarpara, Guwahati, Assam 781009

Factory Address

Harlibagan, Byrnihat - 793101, Meghalaya

COPYRIGHT 2024 PAWAN CASTINGS. DESIGNED BY DIGIBRILLIANCE